Aluminum Coil Color Coating Machine Production Line

Release time:2022-11-11

Number of browsing:358

Author:EVERTOPEST

Aluminum CoilColor Coating Production LineHongyang machinery has the advance production line for coating the aluminum coil, it can be suitable for high gloss, polyester, PVDF, FEVE, mirror, stone, woo···

Aluminum Coil Color Coating Production Line

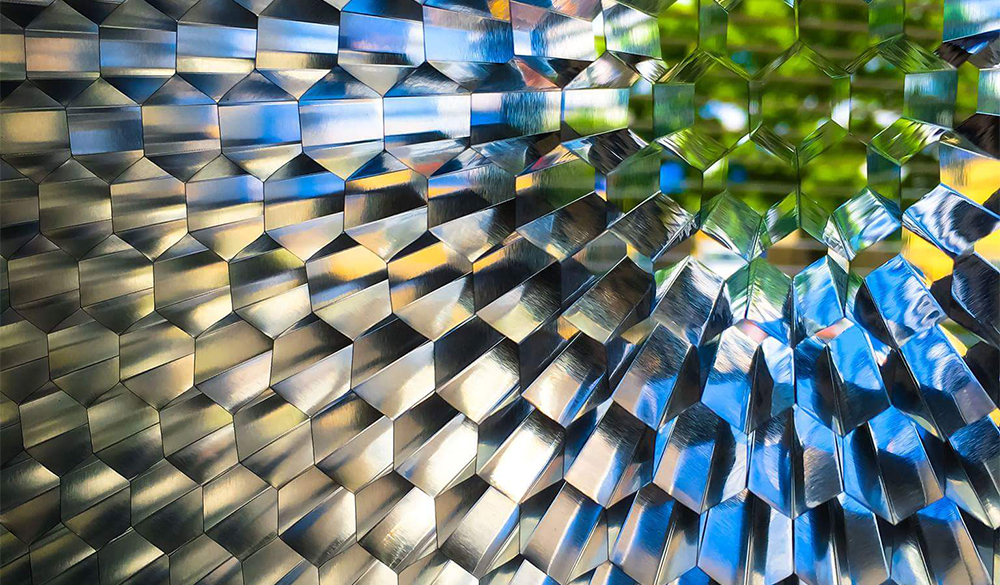

Hongyang machinery has the advance production line for coating the aluminum coil, it can be suitable for high gloss, polyester, PVDF, FEVE, mirror, stone, wooden, water paint etc.

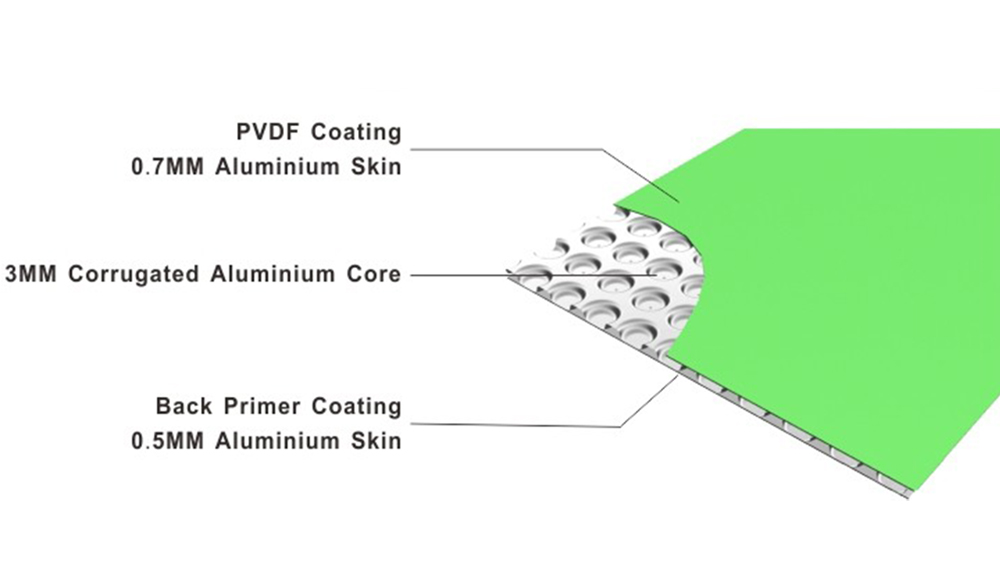

All this coated coil can be used for Aluminum composite panel, wall cladding, facades, roofing, signboards, blind window, electrical panel, kitchen panel, food container, bottle cap, etc.

Structural Composition

The Advanced Aluminum Color Coating Production Line

The production line is designed by Hongyang Machinery, which used to describe the application of a decorative and /or protective organic coating to metal supplied in coil form.

To design a line to meet the customer’s capacity requirements, Hongyang requires a reference coil width and thickness, together with maximum/minimum thickness and widths. The reference strip is the strip size most commonly processed. With this information our designers are able to determine:

1. The thermal capacity of the oven and the strip contact time in the oven and/or

2. The maximum process section line speed

The initial selection of these parameters must be suited to the desired output. To purchase a line with excess capacity would be over-capitalising, and one with insufficient capacity means losing market share.

Pretreating System

No matter what the feed coil type, the strip must be pre-treated before paint is applied to obtain any acceptable level of prolonged paint adhesion and corrosion resistance.

Prior to pre-treatment the feed is cleaned to remove oil and any other surface contaminants. This is done in high pressure spray tanks with contact times of between 2 and 5 seconds. The solution is normally hot (60 -70 degC) alkali although acid based cleaners are also available. Following the cleaning tanks usually two hot (50 -60 degC) water spray tanks are used to be sure that the alkali from cleaning is not carried through to the pre-treatment stage. Between each spray tank rubber squeegees also prevent carry through of the solution from one tank to the next.

Following cleaning, the pre-treatment is applied. This is usually chromic or phosphoric acid based although chromium free systems are now available. The pre-treatment performs a dual function.

● It creates a very high bond between the paint and the base metal.

● It provides corrosion protection. Without the pre-treatment protection, any cuts,

S-Type Coater System

This machine is the most popular machine used. The main advantage of this machine is that the Top Head paints the strip as the strip is supported around a large diameter Back-Up Roll. This Back-Up Roll supports the strip and keeps it very flat so the painting process can be done very accurately. This machine provides very good operator access and visibility on both the top and bottom sides of the strip.

C-Type Coater System

This machine is also a modification of the S-Type Coater Machine. It operates in a similar manner to the U-Type Coater Machine in that it is also a Color Quick Change Coater. The main difference here is that the two Back-Up Rolls are positioned vertically above each other whereas in the U-Type Coater Machine, the Back-Up Rolls are positions horizontally apart from each other.

Baking Oven System

The oven fan blade all use the SS304 stainless steel, and the whole body used 200 thick thermal insulation cotton wool, so the oven surface can't feel any extra heat.

Such kind high-performance floatation oven for drying the solvents stands out for even heating performance, and exceptionally high efficiency. To ensure a flawless finish, the strip travels contact-free through the entire furnace.

Automatic Electrical Control System

Hongyang's machine all standard use the Schneider brand low voltage components.

The Plc, HMI, all choose the Siemens brand. The Inverter choose the ABB brand.Which all world famous. It makes customer satisfy the system stability.

RTO System (Regenerative thermal oxidizer)

The solvent-containing gasses are exhausted from the oven and cleaned in an RTO with high thermal efficiency. Depending on the solvent content in the exhaust air it is possible to operate the post-combustion system and, when using a highly efficient energy recirculation system, the ovens without feeding additional energy.

EPC Rewinding System

In order to get perfect rewinding edge for the coil roll, Hongyang cooperated with famous brand EPC &CPC system company, to make the strip automatic rectify the position of the strip, make sure strip always in the center with right tension. When in rewinding process, the EPC system can make the edge smooth, also can make staggered.

Application

● Roofing &wall cladding

● Guttering

● Fences &walls

● Whitegoods

● Roofing tiles

● Pop can

● Composite panel

● Solid aluminum

● Office furniture

● TV board

● Sports equipment

● Windows shades

● etc.